Concrete Testing Near Me: A Keystone of Project Top Quality and Compliance

Wiki Article

Putting Concrete to the Test: Introducing the Tricks of Product Stamina

Regardless of its extensive usage, the secrets of concrete's exceptional strength stay mostly hidden. In this conversation, we will certainly dig into the structure of concrete, the factors that affect its toughness, and the innovative techniques employed to gauge and improve its performance.The Structure of Concrete

Concrete is a composite material being composed of a combination of cement, water, aggregates, and often other additives. This mix supplies concrete with its unique residential or commercial properties, consisting of stamina, flexibility, and toughness.The dimension and shape of the accumulations can influence the workability and toughness of the concrete. These ingredients can enhance the workability, decrease the water web content, increase the toughness, or boost the sturdiness of the concrete.

Comprehending the composition of concrete is important for designers and building and construction professionals to create and construct structures that fulfill details efficiency demands. By very carefully picking the type and proportion of each component, the preferred strength and durability of the concrete can be attained. Furthermore, improvements in product science remain to discover new ingredients and combinations that can better enhance the residential or commercial properties of concrete, making it an also a lot more flexible and reputable building material.

Variables Impacting Concrete Toughness

Different types of concrete have differing chemical make-ups, which can affect the toughness of the resulting concrete. Additionally, the dimension and shape of accumulations used in the mix can impact concrete stamina.

Various other aspects that affect concrete toughness consist of making use of admixtures, such as plasticizers or accelerators, the addition of supplemental cementitious products, and the presence of pollutants or impurities in the raw materials.

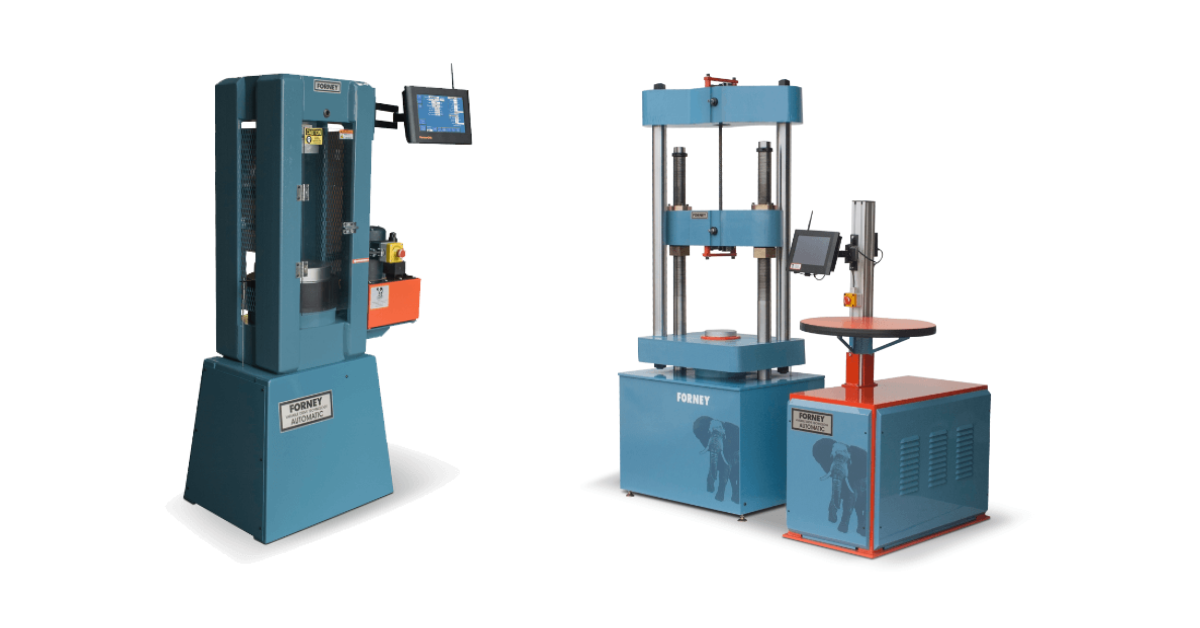

Testing Techniques for Concrete Toughness

One frequently made use of technique for evaluating the stamina of concrete is through the application of numerous testing techniques. One of the most extensively made use of techniques is the compressive stamina examination, which determines the maximum lots a concrete sample can hold up against before it fails.Another essential screening method is the flexural stamina test, which assesses the ability of concrete to stand up to flexing forces. This examination involves subjecting a beam-shaped concrete sampling to a progressively boosting lots up until it reaches its maximum flexing capacity. By gauging the tons and deflection at failing, engineers can establish the flexural stamina of the concrete.

In addition to these examinations, there are other strategies readily available for analyzing concrete strength, such as the split tensile stamina test, the pull-off examination, and the ultrasonic pulse rate test. The split tensile strength test gauges the ability of concrete to stand up to tensile pressures, while the pull-off examination reviews the bond toughness in between the concrete and other products. The ultrasonic pulse velocity test uses acoustic waves to establish the high quality and harmony of concrete.

Enhancing Concrete Toughness

One approach is to use high-quality materials during the concrete manufacturing procedure. Furthermore, incorporating additional cementitious products such as fly ash or slag can enhance the concrete's resistance to chemical strike and minimize leaks in the structure.

Furthermore, effective healing strategies play a crucial function in enhancing concrete toughness. Healing includes keeping appropriate dampness and temperature conditions for the concrete to effectively acquire and moisturize stamina. This process assists protect against breaking, surface flaws, and boosts total toughness.

Future Technologies in Concrete Technology

In the world of concrete innovation, innovations go to my blog imminent promise to more helpful hints change the sector and redefine the opportunities of construction. Researchers and designers are regularly aiming to create cutting-edge techniques and products that can improve the performance and sustainability of concrete.One of the future innovations in concrete innovation is the usage of self-healing concrete. Bacteria embedded in the concrete are turned on upon fracture development, creating sedimentary rock to fill the voids and restore the architectural honesty of the product.

Another location of advancement is using nanotechnology in concrete manufacturing. Nanomaterials, such as carbon nanotubes and graphene, can be included in concrete to improve its mechanical properties. These materials have high toughness and conductivity, enhancing the durability and efficiency of the concrete - concrete testing near me. In addition, nanotechnology can be utilized to create self-cleaning concrete, which reduces the need for routine upkeep and cleaning.

Moreover, researchers are discovering the usage of 3D printing modern technology in concrete building and construction. This technique enables the specific and effective fabrication of intricate frameworks, lowering material waste and construction time. It also opens up new opportunities for architectural layout and customization.

These future innovations in concrete innovation have the potential to change the building and construction industry, making it extra lasting, effective, and cost-effective. With continuous research and growth, we can expect to see these advancements come true in the close to future.

Verdict

In conclusion, understanding the structure of concrete and the elements that influence its strength is important for improving its longevity. Different screening approaches can be used to accurately gauge concrete toughness, supplying important insights for building jobs. As technology proceeds to development, future innovations in concrete innovation hold the prospective to additionally boost the toughness and durability of this vital building and construction product.In addition to these examinations, click here for more there are other methods readily available for examining concrete strength, such as the split tensile strength test, the pull-off examination, and the ultrasonic pulse rate examination. The split tensile toughness test measures the capacity of concrete to withstand tensile pressures, while the pull-off test examines the bond stamina in between the concrete and various other products.One of the future developments in concrete innovation is the use of self-healing concrete. These materials have high strength and conductivity, enhancing the longevity and performance of the concrete. As modern technology proceeds to advance, future developments in concrete modern technology hold the possible to better boost the toughness and toughness of this crucial construction product.

Report this wiki page